When a common fault occurs on the embedded industrial computer motherboard, it is generally repaired by checking the board, troubleshooting and disassembly. How should we correctly use this method to deal with the common fault of the embedded motherboard?

1、 Check board

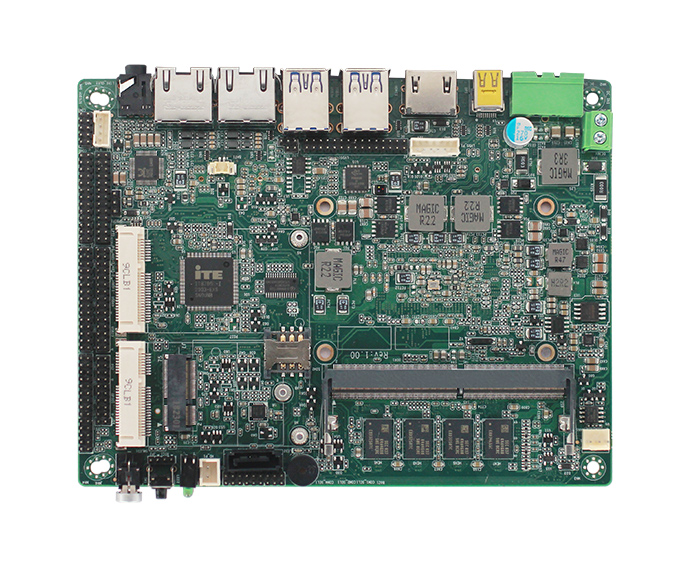

1. Observe: whether there is combustion, combustion, bubbling, surface falling off and rust of Jack.

2. Meter test method: + 9V, GND resistance is very small (less than 50 ohms).

3. Check the power supply: for the damaged industrial automation motherboard, the voltage can be slightly increased by 0.5-1v. After startup, the integrated circuit on the clothing board will be rubbed by force, so that the bad integrated circuit will be identified by heating.

4. Logic pen check: check whether the data signals on the input, output and control poles of the key suspicious integrated circuit are available and whether they are high or low.

5. Identify each working area: the embedded industrial computer motherboard generally has clear responsibilities in this area, such as protection area, digital clock area, situation interface area, attitude area, noise generation area, etc.

II. Troubleshooting

1. According to the instructions of the guide, the suspicious integrated circuit will first check whether there are data signals at the input and output terminals. If there are no data signals at the input and output terminals, check whether the integrated circuit has any control data signals. If so, the integrated circuit is very likely to be broken, and there is no control data signal, so the previous pole can be verified until the damaged integrated circuit is found.

2. It is not necessary to take out the integrated circuit with the same model, specification or program flow content from the electric pole. After starting up, observe whether the embedded industrial computer turns well to determine whether the integrated circuit is damaged.

3. Find a short circuit by means of disconnection and leakage: if you find a short circuit fault between some communication lines and ground wire, + 9V or several other integrated circuits that cannot be connected, you can disconnect the line and measure it accurately to distinguish whether it is an integrated circuit problem or a surface wiring problem, Or see if the status interface is better than other integrated circuits welded to the integrated circuit with wrong waveform with data signal, and distinguish the advantages and disadvantages of the integrated circuit.

4. Comparison method: find a motherboard with the same content, compare and accurately measure the pin waveform and quantity of relevant integrated circuits to determine whether the integrated circuits are damaged.

5. Use ictest to automatically test integrated circuits in microcomputer general development board.

III. disassembly and assembly

1. Cutting and kicking method: it will not hurt the main board and cannot be reused.

2. Tin dragging method: solder all the tin on both sides of the integrated circuit pin, drag it back and forth with a high-temperature soldering iron, and pull out the integrated circuit (the circuit board is easy to be damaged, but the detection integrated circuit can be retained).

3. Baking string: place the baking string on the alcohol burner, gas stove and heating furnace, and the integrated circuit will come out after the tin on the main board melts (difficult to master).

4. Tin pot method: make a special tin pot in a heating furnace. After the tin is melted, the integrated circuit to be unloaded on the main board can penetrate into the tin can. The integrated circuit can be lifted out without damaging the main board, but the mechanical equipment is not easy to manufacture.

5. Electrothermal gas welding gun: use a special electrothermal gas welding gun to remove the chip and blow off some IC pins to be removed, so that the integrated circuit after tin melting can be taken out.

in addition, a common problem of embedded industrial computer is that you must press F1 key after starting up. The reason for this problem is that the complementary metal oxide semiconductor setting is wrong. When the embedded industrial computer starts self-test, it will find that some machines and equipment are not installed, so it will remind you to press F1 again. However, if the machine and equipment are turned on in a complementary metal oxide semiconductor, the above problems will occur. After boot, select the advanced setting option from the basic I / O system settings of the industrial control computer, find the floopyseek in the laidan, and set it to disable.

Service Hotline

Service Hotline